As a manufacturing company and in a generalised context of shortage of raw materials, at ALCAD we set ourselves the challenge of improving our manufacturing processes with the aim of continuing to provide the best service to the customer. The result has been spectacular: thanks to the 'Demand prediction' project and by means of Artificial Intelligence, we are able to understand and anticipate the demand of approximately 500 references three months in advance.

The development of this tool has been possible thanks to Orange Spain and CEPYME, through the CreCEPYME programme. Since its implementation, it has enabled us to reduce by more than 50% the average deviation of the initial predictions in half a thousand references, thus optimising our production processes to provide a satisfactory response to market demand.

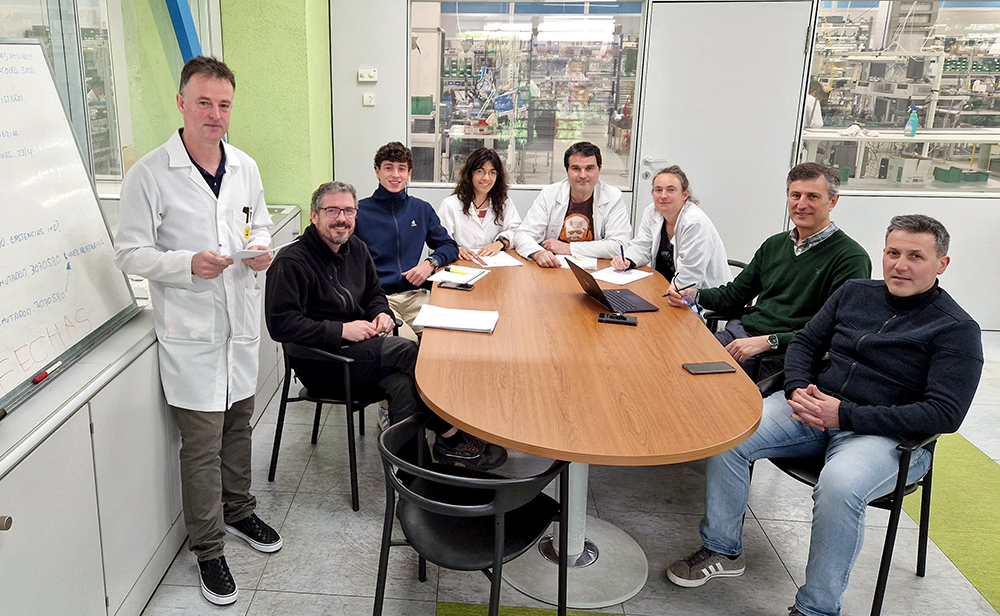

This translates into reduced inventory and improved lead times, allowing us to make more informed and strategic business decisions. In addition, it will save time and effort in production planning by the team in charge of its management, which meets periodically to make medium-term forecasts and carry out the necessary adjustments in the short term.

In the image, from left to right: Agustín Arzuaga (Production Manager), Mikel Eizagirre (Logistics Manager), Unai Arteaga (Purchasing Technician), Enara Navarro (Planning Technician), Josemari Garrucho (Production Coordinator), Maider Gaztelumendi (Production Coordinator), Xabier Isasa (Supply Chain Manager) and José Luis Toledotxiki (Purchasing Manager).

In short, the project has not only validated the effectiveness of Artificial Intelligence in forecasting demand, but has also highlighted our commitment to innovation and excellence in our sector.

Anticipating market demand

Xabier Isasa, ALCAD's Supply Chain Director, explains that "the objective we set ourselves was, based on historical sales, to understand and anticipate the demand for approximately 500 references in our product catalogue in 3 months' time."

The process lasted several months "and covered all the phases of the analysis process. The first part was the definition of the project based on the needs we had in ALCAD, together with the mentor company and taking into consideration their areas of expertise."

As he points out: "Once the project was identified, we held a session to share ALCAD's needs and the information available. From there, there was an exchange of information, and subsequently Orange developed the calculation tool."

Finally, "we carried out several tests together and ended up with the implementation of the application in production, which is now being used throughout the company's industrial area."

The balance, therefore, could not be more positive. "The end of the project has been to obtain a tool that allows us to plan the units to be manufactured during the following quarter based on the sales history."

This initiative is part of the CreCEPYME Project, promoted by CEPYME (Spanish Confederation of Small and Medium Enterprises) and designed to boost business growth. Thus, large companies help SMEs in the development of a specific project, which in our case was oriented to demand planning through Artificial Intelligence.

In this regard, we would like to thank the invaluable collaboration of the CEPYME team, as well as Miguel Ángel Carcelén and Carmen Reina, both from Orange Spain, the mentor company.

Any questions? Please contact us. We will be happy to help you.